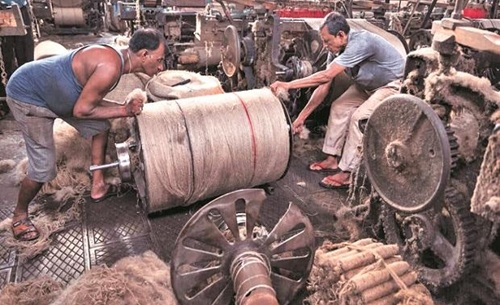

In 2025, India’s jute industry sits at an inflection point: historically a backbone of rural employment and eco-friendly packaging, it now faces simultaneous opportunity and disruption. Demand for biodegradable materials is rising globally, policy support is strengthening, and value-added product innovation is accelerating — yet production volatility, climate risks, and supply-chain constraints are forcing players to rethink strategy. This article reviews where the sector stands in 2025, what’s driving change, key risks, and what businesses should do to benefit.

Market Overview

India remains the world’s largest producer of raw jute, accounting for a significant share of global output and supporting millions across cultivation, processing and manufacturing. Official textile ministry and jute board figures show India producing close to 9–10 million bales in normal years, though 2024–25 saw production stress in some regions due to extreme weather and localized crop losses. At the same time, demand for jute bags, geo-textiles and diversified jute products has strengthened because of plastics bans and corporate sustainability goals.

What’s driving growth in 2025

- Green demand & regulatory tailwinds — Plastic restrictions at national and state levels, plus buyer ESG commitments, are pushing public procurement and retailers toward jute-based packaging and promotional products. Global sustainability trends (and corresponding market reports) project steady growth in jute bags and allied products over the coming decade.

- Policy & institutional support — The Ministry of Textiles, National Jute Board and state governments continue focused interventions: MSP (minimum support price) policies for raw jute, cluster development, common facility centres, and farmer support programs to stabilise income and improve fibre quality. These measures are geared to increase farmer participation and encourage backward-linkages into higher-margin goods.

- Value-addition & product diversification — Traditional sacking and hessian remain important, but manufacturers are investing in value-added segments: fashion & lifestyle jute, laminated jute for durable packaging, geo-textiles for infrastructure, home textiles, and composites. This shift improves margins and reduces exposure to commodity price swings.

Structural challenges & near-term risks

- Climate and production volatility: Floods and erratic monsoons have dented output in recent seasons, with some estimates suggesting meaningful drops in FY2024-25 production. Climate resilience and crop diversification are urgent priorities.

- Processing & quality constraints: Many small jute mills require upgrades in retting, fibre processing and mechanisation to meet higher quality standards demanded by international buyers.

- Supply-chain dependence & imports: Although India is a leading producer, certain specialty jute grades and machinery still rely on imports; logistic bottlenecks and currency shifts can inflate costs.

- Market concentration & price cycles: Over-reliance on a few product lines (sacks/hessian) or markets exposes exporters to demand shocks and price pressure.

Opportunities that matter in 2025

- Packaging substitution at scale: As FMCG, e-commerce and institutional buyers reduce plastics, jute is becoming the default sustainable alternative for many use cases — from multi-use shopping bags to retail packaging. Market forecasts show the jute bag segment expanding rapidly over 2025–2033.

- Geo-textiles & infrastructure: Jute geo-textiles for soil erosion control and civil engineering present a fast-growing B2B opportunity as governments invest in green infrastructure.

- Branding & lifestyle segments: Collaborations with designers, surface-printing technologies and blends (jute + cotton/linen) enable premium lifestyle products that fetch higher margins.

- Exports & market diversification: Rising global interest in biodegradable materials opens doors beyond traditional markets — careful market intelligence and certifications can accelerate export growth.

Strategic actions for stakeholders

- Strengthen farm-to-mill linkages — invest in farmer extension, better retting techniques and contract farming to stabilise fibre quality.

- Upgrade processing & CFCs — scale common facility centres, mechanised spinning and finishing to meet international quality norms.

- Product R&D & branding — develop laminated jute, blends, printed lifestyle ranges and certify eco-claims to command premium pricing.

- Climate resilience — build contingency planning, diversified sourcing corridors and invest in crop insurance or adaptive agronomy.

- Policy engagement — leverage MSP, subsidies and export promotion schemes; push for government procurement mandates for jute in public projects.

Conclusion

In 2025, India’s jute sector combines legacy strengths (scale, raw material endowment, artisan skills) with a favourable structural tailwind from sustainability trends. But to convert demand into durable revenue and rural prosperity, the industry must tackle production volatility, modernise processing, and move decisively up the value chain. If policymakers, farmers and manufacturers align on quality, climate resilience and innovation, jute can reclaim its role as a strategic, green industry for India’s next decade of growth.